Common Types of Plastic

Nowadays plastic things are used everywhere. From the brushes, toilet lid, trash can, covers for all kinds of electrical appliances, storage containers in our daily life, to application in packaging field, construction field, electronic field, auto industry, and also in medical and health field etc. We can see them from the first eye in the morning.

The advantages of plastic products are obvious to the common people. For example, before plastic stools appeared, every household used wooden stools. Wooden stools are not only heavy and waste wood processing cycle is also long. All situations changges when the plastic bench comes. The industrial production using a molding hot pressing technology. We can produce ten thousands of plastic benches one day. They are cheap, colorful, resistant to falling. The emergence of plastic products, greatly reduce the use of wood and other materials, protect the forest resources, but also bring great convenience to people’s lives.

So how many different kinds of plastics are common in our lives? What are their strengths and weaknesses? What plastics can and cannot be used for food?

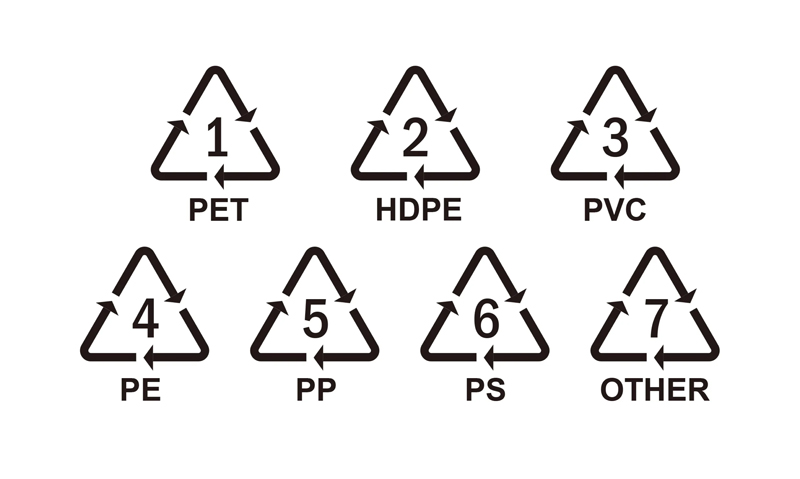

We often find signs at the bottom of a plastic sheet like below:

- PET-Polyethylene terephthalate (polyester)

“No. 1” PET commonly in: mineral water bottles, carbonated beverage bottles, fridge containers etc.

Use: heat-resistant to 65 °C, cold-resistant to-20 °C, only suitable for filling warm or cold drinks. If it is filled with high-temperature liquid, it is easy to go deformation. There are harmful substances melting out under high temperature. Moreover, the scientists found that Plastic No. 1 May release the carcinogen DEHP after 10 months of use, which is toxic to the testes. Therefore, drink bottles and so on ran out of throw away, do not use as a water cup, or used to do storage containers loaded with other items, so as not to cause health problems. Caution: do not recycle beverage bottles for hot water. Cannot place them in the car in the Sun; do not install alcohol, oil and other substances.

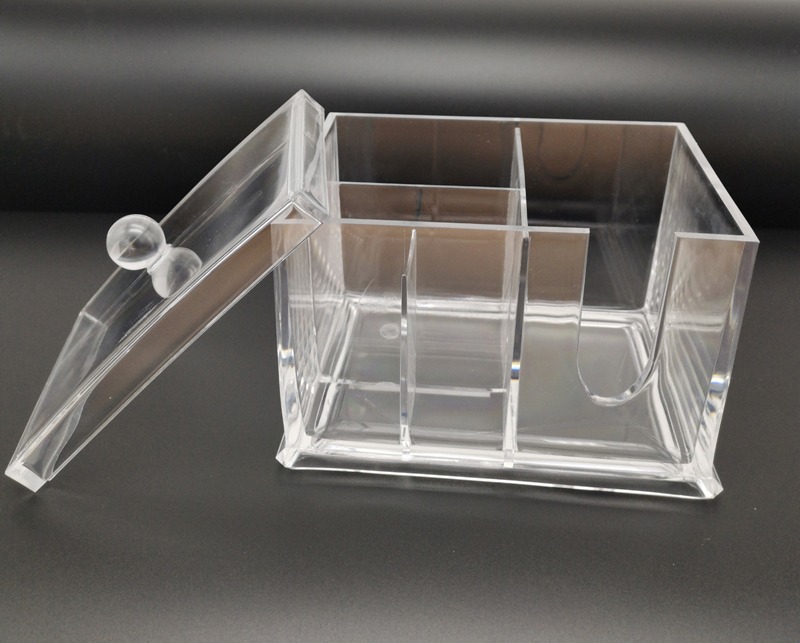

The PET material is also for refrigerator boxes since its cold tolerance. All kinds of storage containers are designed for storage vegetables, fruits, meat, and all kinds of food. They are with clear see through design, help you easily get what you want by an instant glance.

- HDPE- High density polyethylene

“No. 2” HDPE commonly used in: cleaning supplies, bath products packaging.

Use: can be reuse after carefully cleaning. But these containers are usually not easy to clean. Residual of cleaning supplies becomes a hotbed of bacteria. You’d better not use them again like recycle things. Don’t use it as a water bottle or as a storage container for anything else.

Note: It is difficult to clean thoroughly and it is not suitable to recycle.

- PVC- polyvinyl chloride

“No. 3” PVC commonly used: common raincoat, building materials, plastic film, plastic box and so on. Rarely used for food packaging.

Use: this material is flexible and cheap, so it is very common to use. It can only withstand heat 80 °C. If you use it under high temperature, it’s easy to produce harmful substances. Even the process will release toxic substances. If you use it as food container, it may cause breast cancer, birth defects and other diseases. Containers of this material have been used less for food packaging. If used, do not allow it to heat up. Difficult to clean and easy to residue, do not recycle. Don’t buy drinks if they are packed.

Note: Do not use for food packaging.

- LDPE- Low density polyethylene

“4” LDPE commonly used: plastic film, plastic film and so on.

Use: its heat resistance is not strong. Usually qualified PE film in the temperature of more than 110 °C will appear hot melt phenomenon, will leave some plastic that our body cannot decompose. The fat from food is also very easy to dissolve fresh film and make it evolve harmful substances. Therefore, before the food is heated in microwave oven, you have to remove the wrapped plastic firstly. High temperature produces harmful substances, toxic substances into the human body with food, may cause breast cancer, birth defects and other diseases.

Caution: Heat in the microwave, do not wrap food in plastic wrap.

- PP- Polypropylene

“No. 5” PP-we commonly use it in: soy milk bottles, yogurt bottles, juice drinks bottles, microwave lunch boxes.

Use: its common melting point is up to 167 °C. It is the only safe plastic to put into the microwave oven, and can be cleaned and reused. We have to pay special attention to the fact that some microwave lunch boxes using different plastic for the body and lid. Please make sure the part you put into microwave oven is PP plastic but not others. Sometimes the lunch box lid is PET plastic but not PP. So you have to take the lid off when you put the box into oven. Because PET cannot withstand high temperatures, it cannot be put into the microwave oven.

Note: When you put your lunch box in the microwave oven, please make sure the material of box is made of PP plastic.

- PS-Polystyrene

“No. 6” PS commonly used in: Bowl packed noodle box, fast food box.

Use: the material is heat-resistant and cold-resistant, but it is not suitable to put into the microwave oven. We do that to avoid excessive temperature. It may release chemicals (70 °C when released) under high temperature. And we cannot use it to hold strong acid (such as orange juice), strong alkaline material. Because it sometimes releases bad polystyrene to the human body which is easy to cause cancer. Therefore, you should try to avoid using fast food box packing hot food.

Note: do not microwave instant noodles in a bowl.

- PC- Other plastics

“7” PC other categories commonly used: Kettle, cup, bottle.

Use: a widely used material, especially in baby bottles, etc. It is well known as a controversial material because of its BPA content. But according to the theory of a biology and chemistry professor, if 100 percent conversion is finished from BPA to PC plastic structure, it means that the PC plastic is completely free of BPA. There is no need to worry about BPA releasing from the PC products. However, if a small amount of BPA is not converted into the plastic structure of PC, it may be released into food or drink. Therefore, we have to take care when using this kind of plastic container. Remember to buy the products with certification that free of BPA.

Suggestions on cleaning measures against BPA

The higher the temperature is, the more BPA is released and the faster the release speed does. Therefore, do not use PC water bottles to hold hot water in order to avoid increasing the rate and concentration of BPA (if any) released. If your kettle is number 7, the following methods can reduce the risk:

- Do not heat when in use.

- Do not use a dishwasher or a dishwasher to clean the kettle.

- Keep the kettle out of direct sunlight.

- Wash with baking soda powder and warm water before first use, and dry naturally at room temperature. Because plastic products release more BPA in the first and long-term use.

- If the container is broken or damaged in any way, it is recommended not to use it. Becasue the plastic is prone to hiding bacteria if it has small pits on the surface.

- Avoid the repeated use of aged plastic appliances.

What’s the difference between PP and PET?

- PP plastic

We produce Polypropylene by a process called chain-growth polymerization from monomer propylene. It is odorless, tasteless, non-toxic, one of the lightest resins commonly used. It has excellent mechanical properties, good heat resistance, continuous use temperature up to 110-120℃. The chemical stability is good, except the strong oxidant, does not have the function with most chemical drugs. PP is a food safe material.

PP has excellent water resistance, excellent electrical insulation. But it is easy to aging, low temperature impact strength is poor. Application areas, for the production of injection molding products, film, pipe, plate, fiber, paint and so on. Widely used in household appliances, steam, chemical, construction, light industry and other fields.

- Polyethylene (PET) plastic

Polyethylene is the most commonly available plastic in the world. One-third of the global plastic consumption is PET. PET is also polyethylene terephthalate. It is an opalescent or yellowish, highly crystalline polymer with a smooth, glossy surface. It has excellent physical and mechanical properties in a wide temperature range, excellent electrical insulation, even at high temperature and high frequency, its electrical properties are still good, but its corona resistance is poor, and its creep resistance is poor, fatigue resistance, friction resistance, dimensional stability are very good.

There are many variants of PET available in the market differing in the manufacturing processes and characteristic properties. Take the most often drink bottles for example, it is not resistant to high temperature. The bottle will be out of shape when temperature is over 60℃-70℃.

Is PP safer than PET as food container?

- MATERIAL SAFETY

PET is also polyethylene terephthalate (Pet). We commonly use it in the packaging of mineral water bottles and carbonated drinks. PP material, also known as polypropylene. We mainly use it in soy milk, fruit juice and microwave lunch boxes. We make many housewares with PP material . PP and PET plastic material are all odorless, tasteless, non-toxic, safe to make food containers.

- TEMPERATURE

PET high temperature resistance is not very good. It can only withstand 70 degrees Celsius at most. Beyond this temperature it will appear deformation. And it release harmful substances to the human body. It can not be exposed to the sun. The PET products can not hold alcohol, oil. It release carcinogenic DEHP if used for more than 10 months. PP melting point can be up to 167 degrees Celsius. It is the only plastic that can be used to make microwave heating materials. After cleaning we can use repeatedly. It is now the world recognized high safety, use a wide range of materials, has become many factories and the industry’s preferred material.

- CONCLUSION

Food PP and pet materials are actually good, but general speaking PP materials with the safety and heat resistance, security is better. so we are widely using this material in our life, but it depends on the scope of the application.